Smart capacity requirements planning (CRP) helps your business stay on track by matching resources with demand, avoiding delays, and controlling costs. By predicting future demand and making sure the right resources are available, CRP prevents bottlenecks and keeps operations smooth. In this article, you‘ll learn how to implement CRP, whether manually or by using tools like Birdview PSA. Whether you‘re in IT, engineering, or manufacturing, these strategies will help you manage resources proactively, meet deadlines, and keep clients satisfied–all while reducing unnecessary costs.

What is capacity requirement planning (CRP)?

Capacity requirements planning (CRP) is the process of making sure your business can meet its production goals. It involves comparing your planned production schedules with your actual capacity to identify any gaps or surpluses. With CRP, you can:

👉 Forecast demand to understand future needs

👉 Allocate resources proactively to meet those needs

👉 Align production with customer requirements

This process helps you avoid overproduction or resource underutilization, keeping everything in balance. It makes sure you’re prepared for growth without wasting valuable resources.

Tools and software for CRP: features and benefits

| Tool/Software | Description | Key Features | Benefits for CRP |

| Capacity planning tools | These tools focus on managing capacity using real-time data and predictive insights to simplify decision-making. | – Real-time capacity tracking

– Scenario modeling – Integration with production systems |

– Helps make quick decisions when needs change

– Keeps operations running smoothly – Spots bottlenecks early to avoid delays |

| Scheduling software | Built to organize production schedules, these tools align timelines with resources and demand. | – Gantt charts for visual planning

– Automated scheduling |

– Keeps production timelines on track

– Makes the best use of available resources – Reduces idle time and schedule conflicts |

| Material requirements planning (MRP) systems | These systems synchronize inventory, production schedules, and materials to match demand and avoid shortfalls. | – Real-time data updates

– Forecasting capabilities – Bill of materials (BOM) integration |

– Helps maintain proper stock levels

– Aligns material availability with production plans – Avoids disruptions caused by mismatched inventory |

Manual capacity requirement planning vs. Birdview PSA

Managing capacity requirements can be done either manually or through an automated system like Birdview PSA. Below is a clear comparison to show how Birdview PSA makes the process faster, more accurate, and scalable – especially for growing businesses managing multiple projects.

1. Manual capacity requirement planning

Manual capacity planning involves a series of steps to match your available resources with project needs. Here’s how the process works:

Steps to calculate capacity requirements manually

1️⃣ List tasks and activities

Start by listing out all the tasks and projects that need to be completed. This helps you see the full scope of work and understand which resources are required.

2️⃣ Estimate time needed

Next, estimate how much time each task will take. You can use past project data to guide these estimates, but there‘s always a risk of underestimating or overestimating.

3️⃣ Check resource availability

Look at your team‘s availability – how many hours can your employees or machines work? This gives you a clear picture of how many resources you have to allocate.

4️⃣ Compare demand vs. supply

Compare the resource demand for your tasks against the available resources. Any mismatch between demand and supply will require you to make adjustments.

5️⃣ Balance resources

If resources are overbooked or underutilized, you‘ll need to manually adjust the plan by reallocating tasks or shifting timelines to ensure balance.

Challenges with manual capacity requirement planning

While this method has its benefits, it comes with challenges:

| Challenges | Description |

| 👉 Time-consuming | Tracking everything manually takes up a lot of time and can be overwhelming. |

| 👉 Prone to errors | It’s easy to make mistakes, especially when working with a large amount of data. |

| 👉 Difficult with multiple projects | Managing several projects at once gets harder without a clear way to keep track of everything. |

| 👉 No real-time adjustments | Without tracking in real time, it‘s tough to make quick changes when unexpected issues arise. |

2. Using Birdview PSA software for capacity requirement planning

Birdview PSA eliminates the manual hassles by automating capacity planning. It offers real-time tracking, AI-powered forecasting, and centralized visibility, ensuring you can make accurate decisions quickly and efficiently.

Here‘s a direct comparison of how Birdview PSA addresses the challenges of manual planning:

| Manual Planning Challenge | How Birdview PSA Solves It |

| Time-consuming | Birdview PSA automates the tracking of tasks, resources, and timelines, significantly reducing time spent on manual work. |

| Prone to errors | With automated calculations and real-time data inputs, Birdview PSA minimizes the risk of human errors in capacity planning. |

| Difficult with multiple projects | Birdview PSA provides a centralized dashboard to manage multiple projects simultaneously with Gantt charts, calendars, and Kanban boards. |

| No real-time adjustments | Birdview PSA offers real-time insights and AI-driven forecasts to make instant adjustments and avoid bottlenecks. |

Key features of Birdview PSA for capacity planning

| Feature | What It Solves | Why It‘s Better |

| Activity Center | View tasks and projects in Gantt charts, calendars, or Kanban boards. | Helps visualize workload across multiple projects in one place. |

| Time Tracking | Track how much time has been worked, billed hours, and approved hours. | Ensures you have a clear picture of current resource availability. |

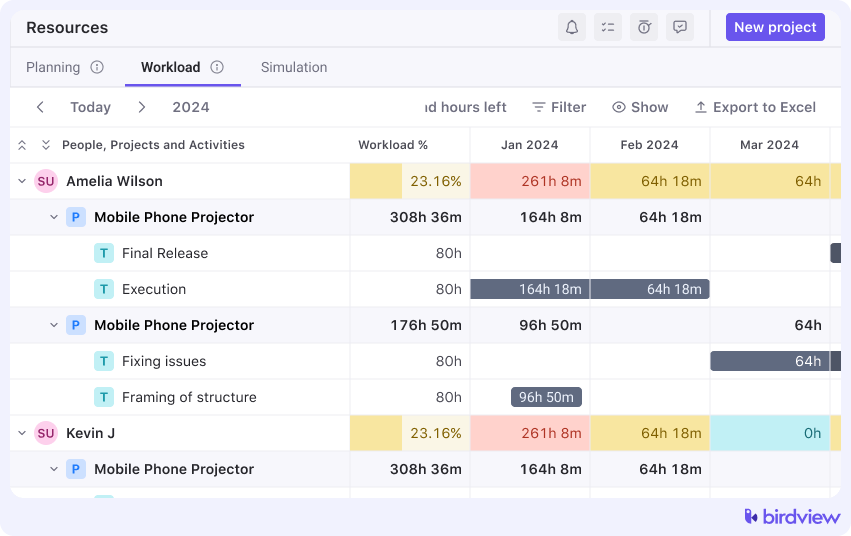

| Workload Tab | Monitor each team member‘s workload and reassign tasks if necessary. | Helps balance workloads to prevent burnout and improve efficiency. |

| Planning Tab | Assign resources to tasks and simulate different scenarios to find the best fit. | Ensures you always have enough capacity to meet project demands. |

| Reports & Dashboards | Create custom reports to see resource usage trends and capacity gaps. | Helps you spot areas where resources may be overbooked or underutilized. |

| AI Forecasting | Predict future resource needs based on historical data and trends. | Allows you to plan ahead and avoid resource shortages before they occur. |

Why is Birdview PSA a better choice?

✅ Save Time – Automate manual processes to free up time for more strategic work.

✅ Improve Accuracy – Eliminate errors with real-time data and automated calculations.

✅ Manage Multiple Projects Easily – Use centralized tools to track and balance workloads across different projects.

✅ Make Real-Time Adjustments – Respond quickly to changes using AI insights and real-time tracking.

In short, Birdview PSA turns capacity planning from a cumbersome manual process into a streamlined, efficient workflow.

Capacity requirement planning process: What are the steps for capacity requirements planning?

Planning for capacity helps you stay ahead of demand. Let‘s dive into the key steps to make sure you‘ve got the right resources when you need them.

1️⃣ Predict future service needs: forecast resource demand

Accurate resource forecasting is the key to keeping projects on track. Predicting what you‘ll need ahead of time helps prevent having too much or too little.

Both scenarios can delay progress and stretch budgets. Start by collecting data like sales forecasts, project timelines, and production schedules. This information doesn‘t just show what resources you need–it also reveals patterns across different teams or tools.

Looking at past projects, market trends, and business goals will give you a solid idea of what’s coming.

But predicting future needs isn‘t always straightforward. If you get it wrong, you might end up overstaffing or facing shortages, which can mess up timelines.

💡 How Birdview PSA can help

Birdview PSA‘s AI forecasting feature makes it easier to predict what resources you‘ll need.

With its Gantt charts, calendars, and dashboards, project managers can see what‘s coming up. This gives them a clear picture of upcoming workloads, helping them stay ahead and avoid any surprises.

2️⃣ Assess available resources and capacity

Once you know what you‘ll need, the next step is to check what you have. It‘s important to evaluate your current resources–whether that‘s staff, equipment, or infrastructure. This helps you spot any gaps before they become an issue.

You‘ll also want to review your team‘s availability and skills to make sure you‘re not overloading anyone or leaving resources underused.

Skipping this step could lead to delays, spiraling costs, and lower-quality results.

💡 How Birdview PSA can help

Birdview PSA‘s workload tab gives you a live view of team availability and resource status.

You can easily spot which employees are overloaded, which ones have space for more tasks, and where potential bottlenecks might form.This visibility helps you make proactive decisions and avoid overworking the team or wasting resources.

3️⃣ Build a demand plan to address resource gaps

Once you‘ve assessed your resources, the next step is to create a demand plan. This plan should detail the resources needed at each stage of the project and point out where you‘re lacking.

Whether you need temporary staff or long-term equipment upgrades, a good plan will help keep your project moving smoothly.

Scenario planning helps you prepare for the unexpected–like a sudden increase in demand or market changes. With short-term and long-term plans, you can adjust when needed, making sure resources are always used wisely.

💡 How Birdview PSA can help

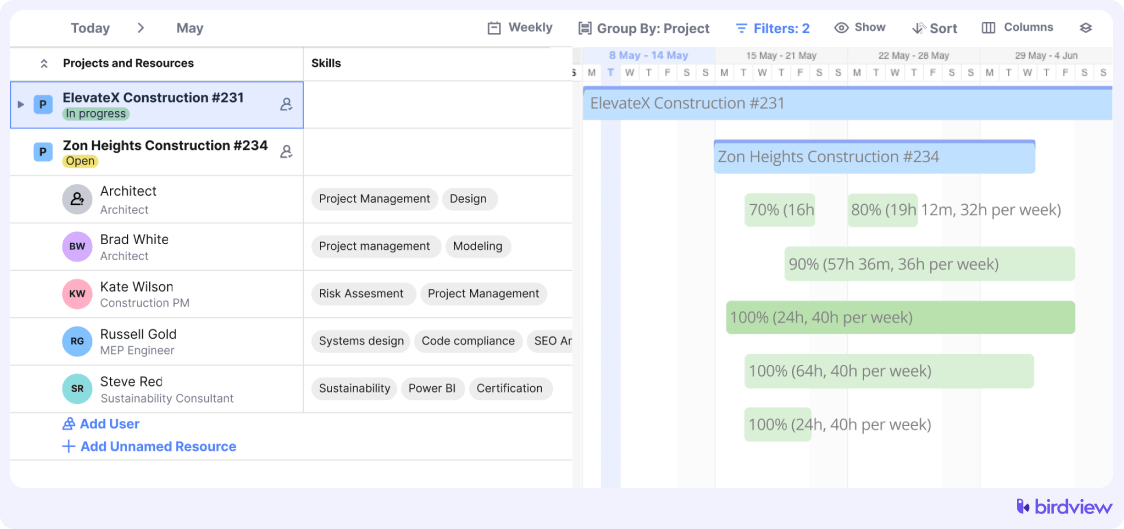

Birdview PSA‘s planning tab lets you allocate resources, adjust your plans, and model future needs.

With custom forms and saved views, your team can keep track of demand and update plans in real time, making sure resources are always aligned with the current project requirements.

4️⃣ Account for limitations and develop backup plans

Every project faces limitations, whether it‘s a tight budget, deadlines, or a lack of skills. If you don‘t plan for these, the project could run over budget or get delayed.

It‘s important to identify potential challenges and create strategies to keep things on track.

This is where backup plans come in. Having these in place means you can respond quickly to unexpected roadblocks without losing momentum.

💡 How Birdview PSA can help

Birdview PSA‘s simulation tab helps you model different scenarios and evaluate risks like budget cuts or skill shortages.

By considering these potential issues ahead of time, you can adjust your plans as needed, keeping the project moving forward without any major disruptions.

5️⃣ Identify capacity changes needed to meet demand

Adjusting your capacity in real-time is necessary to keeping projects on schedule. Whether it‘s hiring more staff, buying new equipment, or redistributing tasks, the key is to act quickly but thoughtfully.

Waiting too long might cause delays, but making changes too early could lead to unnecessary commitments.

💡 How Birdview PSA can help

Birdview PSA‘s resource requests feature lets you identify where there are capacity gaps and request the needed resources.

With custom reports, you can see exactly when to make adjustments, so your team can respond to emerging needs right away, without delay.

6️⃣ Plan for long-term capacity management

Long-term capacity planning isn‘t just about managing today‘s projects–it‘s about preparing for the future. As your business grows, you‘ll face new challenges.

A solid long-term plan helps you stay ahead and manage that growth without falling behind.

Regularly review your capacity plan to adjust for new projects, market changes, and evolving business goals. Being proactive will keep your team ready for anything that comes your way.

💡 How Birdview PSA can help

Birdview PSA‘s reports and dashboards track capacity trends over time, giving you a clear view of how resources are being used.

These insights let you adjust your plans in advance, reducing the risk of running into capacity issues later. With AI-driven metrics, Birdview PSA helps refine your long-term strategy, so you‘re always ahead of demand and ready for growth.

Capacity requirement planning examples

1️⃣ Professional services firms CRP example

Professional services firms often deal with fluctuating workloads. To stay on top of things, they need to plan their resources carefully.

For example, a law firm might know they‘ll get more work during tax season. With CRP, they can plan to bring in extra help when it‘s needed. It also makes sure employees aren‘t overworked or underutilized, making everything run smoother and keeping the quality of service high.

What is capacity requirement planning in professional services?

In professional services, CRP focuses on managing resources like personnel, time, and materials. It includes forecasting project demand, scheduling staff, and aligning resources with service delivery.

The main elements of CRP here are resource forecasting, capacity forecasting, project scheduling, and monitoring utilization. When done right, CRP helps balance workloads and heighten service quality.

How does capacity requirements planning impact professional services industries?

CRP improves resource allocation, which speeds up project delivery and enhances customer satisfaction. It prevents teams from being overloaded or underused, which helps uplift profitability.

By matching resources with client needs, businesses cut down on inefficiencies and improve their market position.

How is capacity measured in the service sector?

In the service sector, measuring capacity is necessary for smooth operations. It‘s done using:

- Utilization rates – How proactively your staff is being used

- Service-level agreements (SLAs) – Making sure you meet agreed-upon service expectations

- Resource availability – Knowing if you have enough staff or materials to meet demand

Tracking these metrics helps you maintain a steady flow of service and avoid downtime, improving customer satisfaction.

2️⃣ Engineering firms CRP example

Engineering firms usually work on large, complex projects. CRP helps them make sure they have the right people and materials at the right time to meet project deadlines.

Take an infrastructure project, for example. CRP helps determine when extra engineers or specialized equipment will be needed. Without CRP, a firm might underestimate their resource needs, leading to delays or extra costs. Planning ahead keeps things on track and within budget.

3️⃣ Consulting firms CRP example

Consulting firms use CRP to manage client projects and make sure they have enough skilled consultants for each one. Since consultants often juggle multiple projects, balancing workloads is key.

CRP helps firms predict when more consultants will be needed.

For instance, if a firm expects a surge in demand for strategic advice, they can hire more or outsource the work. This way, they keep operations efficient and clients happy.

What to consider when using CRP (capacity requirement planning)?

When implementing capacity requirement planning (CRP), focus on these key factors to make sure the process works smoothly.

⚙️ 1. Keep CRP updated

Regular updates keep you ahead of demand changes. Plan checks monthly, quarterly, or annually based on your business cycle.

📐 2. Choose a capacity strategy that fits

👉 Lead = Prepare for future growth.

👉 Lag = Scale only when needed.

👉 Match = Stay in sync with demand.

Pick the right one for your goals!

🔮 3. Nail demand forecasting

Use past data and customer trends to predict what‘s coming. Avoid overproduction and shortages by staying ahead of the curve.

📊 4. Calculate capacity clearly

Take a hard look at your resources, schedules, and workforce availability. Do they align with upcoming demand? If not, adjust!

🎯 5. Prioritize the right projects

Focus on high-impact tasks that align with your business goals. Don‘t waste resources on projects that won‘t move the needle.

📋 6. Regular capacity checks

- What‘s your current team workload?

- Are resources maxed out?

Regular checks = fewer bottlenecks.

📡 7. Centralize tracking

One platform = everyone on the same page. Use a centralized system to track progress, monitor workloads, and stay organized.

Explore ▶️ Powerful PSA, project and resource management software

🤝 8. Collaborate across teams

CRP isn‘t a solo job. Input from all teams ensures no blind spots and helps create a plan that works for everyone.

💻 9. Use smart tech

Leverage capacity planning tools and demand forecasting software to simplify the process and reduce errors.

🔄 10. Monitor & adjust

Don‘t “set it and forget it.”

Stay flexible! Check progress regularly and tweak plans to handle unexpected changes.

What are the factors affecting capacity requirements planning? Challenges in implementing CRP

| Factor | What It Means |

| Workforce availability | You need the right number of skilled workers at the right time. If you‘re short-handed, production can slow down. Proper planning makes sure you’re always ready. |

| Data accuracy | For CRP to work well, you need accurate data. Better data collection improves your forecasts, reduces mistakes, and keeps your planning on track. |

| Unexpected demand surges | Demand can spike unexpectedly. To stay on top, your CRP should be flexible enough to adjust quickly and meet customer needs during these peak times. |

| Integration issues | CRP needs to fit in with your current systems, like scheduling or forecasting tools. Smooth integration means fewer disruptions and better overall productivity. |

| Resource constraints | Limited resources like materials, equipment, or labor can throw off your plans. Tackle these constraints upfront to keep production flowing without hiccups. |

| Change management | CRP requires change, and not everyone will be on board right away. Be transparent, offer training, and provide strong leadership to help your team embrace the shift. |

| Financial investment | CRP tools and systems can be expensive. Make sure you have the budget to cover implementation and long-term use to avoid any financial strain down the road. |

| Product complexity | If your products are complex, your CRP needs to be customized. Plan for different specifications and variations to keep everything running smoothly. |

| Staff availability | Having skilled workers available when you need them is important. Plan staffing carefully to avoid delays, especially during busy times or shortages. |

| Machine capacity | Machines play a big role in your output. Underuse or breakdowns can push production off track. Keep an eye on machine performance to stay on schedule. |

| Supply issues | Supply chain disruptions can mess with your CRP. Build strong relationships with suppliers to minimize risks like delays or transport issues. |

| Resistance to change | Change is tough, and introducing CRP is no different. Overcome resistance by communicating clearly, involving your team, and showing them the long-term benefits. |

Types of capacity requirement planning

Here are some of the major types of capacity requirement planning for your business 👇.

1. Long-term capacity planning: Prepare for growth by planning resource needs several years ahead. This helps businesses adapt to market changes and technology advancements while aligning investments with future goals.

For example, a company expanding globally might invest in scalable technology or build new facilities to handle rising demand.

2. Medium-term capacity planning: Focus on the next 1–3 years to connect long-term strategies with current needs. This type of planning predicts demand shifts and adjusts workforce, resources, or supplier agreements accordingly.

Imagine a retailer preparing for the holiday season by hiring seasonal workers and increasing inventory to handle spikes in demand.

3. Short-term capacity planning: Address immediate resource needs over days to a few months. The goal is to optimize staffing, materials, and equipment to make sure smooth operations.

For example, a manufacturing plant might adjust shifts and stock up on raw materials to handle a sudden influx of orders.

4. Resource planning: Make the most of materials, manpower, and tools by making sure everything is used proactively. This reduces waste and keeps projects on schedule.

For instance, assigning tasks to skilled employees and certifying tools are ready increases productivity and avoids delays.

5. Strategic capacity planning: Tie capacity decisions directly to long-term business goals. This anticipates future needs to support sustainable growth.

A company entering a new market, for example, might evaluate whether they need additional production lines or distribution centers.

6. Rough-cut capacity planning (RCCP): Assess preliminary production plans to find potential bottlenecks early. This helps identify and solve resource shortages before detailed scheduling begins.

For example, if production demand exceeds machine availability, RCCP helps adjust plans to avoid overloading systems.

7. Detailed capacity requirements planning (CRP): Focus on matching specific tasks with available resources. This certifies every production step runs seamlessly.

For instance, precisely scheduling machine hours or worker shifts helps meet deadlines without causing system overloads.

8. Input/Output control: Keep resources balanced by making sure what enters and leaves the system stays consistent. This maintains a steady workflow.

For example, certifying timely deliveries from suppliers prevents production slowdowns caused by shortages.

9. Finite capacity planning (FCP): Work within real-world limitations like staff, equipment, or time constraints. This method creates realistic schedules.

For instance, a bakery with only two ovens can plan its baking schedule to handle orders without overloading capacity.

10. Infinite capacity planning (ICP): Start with an ideal scenario assuming unlimited resources. Businesses often use this as a baseline before refining plans based on actual constraints.

For example, an initial production plan might assume enough workers and machines, but adjustments are made later based on availability.

Best practices for continuous CRP improvement

⏩ Iterative approach

Think of CRP (Capacity Requirements Planning) as an ongoing process, not a one-time task. Regularly compare your plans with actual results to find gaps or inefficiencies.

Use this information to update and improve your planning methods. This keeps your approach relevant and aligned with both current needs and long-term goals.

⏩ Leveraging feedback loops

Pay attention to daily operations and customer feedback to make smarter decisions.

Look at production trends, employee workloads, and customer demand patterns. This data helps you adjust your capacity planning in real time.

By focusing on real-world insights, you‘ll create a system that adapts easily to changing needs while staying connected to your business objectives.

⏩ Staying agile

Build flexibility into your CRP strategy so you‘re ready for surprises. For example, prepare for market changes, unexpected demand spikes, or seasonal trends.

Adjust your resources ahead of time to avoid delays and make the most of what you have. Agility helps your organization respond quickly and keeps things running smoothly.

Explore ▶️ What is agile project management?

What industries utilize capacity requirements planning?

✅ Professional service industry: CRP helps service firms allocate time and personnel proactively to meet client deadlines without overburdening staff.

Explore ▶️ What is professional services automation (PSA)?

✅ IT industry: IT companies use CRP to balance workloads across software development, infrastructure projects, and support tasks.

✅ AEC industry: In construction, CRP schedules labor and materials to prevent delays and keep large projects on track.

✅ Audit & accounting/ legal firms: CRP makes sure that staff are available to meet tight deadlines while avoiding burnout during peak periods.

✅ Automotive: Automotive manufacturers use CRP to align assembly lines with fluctuating customer demand, ensuring efficient production.

✅ Pharmaceuticals and medical devices: CRP helps pharmaceutical companies manage production schedules while complying with strict regulatory standards.

✅ Food and beverage: In the food and beverage industry, CRP optimizes production processes and manages seasonal demand without generating waste.

✅ Consumer products: Consumer goods companies rely on CRP to align production with market trends, manage inventory, and make sure timely deliveries.

✅ Electronics and tech devices: Tech companies use CRP to manage complex design cycles, scale production, and navigate supply chain challenges.

✅ Industrial manufacturing: CRP helps industrial manufacturers allocate machinery and resources proactively to meet varying production needs.

How is capacity requirement planning used in manufacturing?

Capacity requirement planning (CRP) helps manufacturers stay on schedule by matching tasks with available resources. It calculates how much time each activity needs and identifies potential bottlenecks. If a resource is overbooked, schedules are adjusted to avoid delays.

By analyzing workloads, manufacturers can make the best use of machines and workers. This reduces downtime, prevents overloading, and keeps production running smoothly.

With CRP, businesses can meet deadlines, minimize waste, and deliver products on time.

For example:

- If a machine is scheduled for maintenance, CRP makes sure other machines are ready to pick up the slack.

- If a team is short-staffed, CRP can redistribute tasks to keep the workflow steady.

What does CRP mean in procurement?

CRP in procurement helps manage material supply and keeps production moving.

It tracks supplier capacity, monitors delivery schedules, and predicts future needs. If a supplier falls short, CRP allows you to adjust orders or find alternatives before issues arise.

By avoiding shortages or excess inventory, CRP supports uninterrupted production and helps you plan smarter procurement strategies that adapt to demand changes.

Benefits of capacity requirements planning

Let‘s take a close look at the benefits of capacity requirements planning.

▶️ Optimized resource utilization: Make the most of your resources by matching capacity to demand, avoiding both underuse and overuse.

▶️ Improved client satisfaction: Deliver on time and with better quality. Happy customers? Guaranteed.

▶️ Enhanced decision-making: Get the right data to schedule smarter, manage inventory, and allocate resources efficiently.

▶️ Cost monitoring: Cut unnecessary expenses by using resources wisely – think labor, equipment, and time.

▶️ Flexibility to adapt: Quickly adjust to changes in demand without scrambling. Stay ahead of the curve.

▶️ Growth planning made easy: Forecast future needs and scale your business without overextending.

▶️ Improved human capital management: Match the right people to the right tasks. Keep employees engaged and avoid burnout.

▶️ Higher customer service levels: Fine-tune resource allocation to deliver better service, increasing customer satisfaction and loyalty.

▶️ Boost in profitability: By reducing waste and keeping costs in check, CRP leads to healthier profits.

▶️ Continuous improvement: Build a culture of ongoing refinement. Identify gaps and improve processes for long-term success.

Future trends in CRP

- Predictive analytics

Predictive analytics is changing how businesses plan their capacity. By looking at past data and market trends, companies can predict future demand.

- Cloud-based solutions

Cloud solutions have made capacity planning more flexible and scalable. With real-time access to data, businesses can adjust their plans as needs change. Teams can collaborate from anywhere, quickly reacting to shifts in demand without the need for expensive infrastructure updates.

- Integration with IoT

The Internet of Things (IoT) is taking capacity planning to the next level. IoT devices monitor equipment, track inventory, and even predict maintenance needs. With continuous, real-time data, businesses can optimize their resources, reduce downtime, and improve productivity.

- Collaborative planning

Today‘s capacity planning is all about collaboration. Teams from sales, production, and logistics now share insights and align goals. This teamwork makes sure that production can meet demand, improving operations and uplifting performance.

- Sustainability

Sustainability is becoming a key focus in capacity planning. Companies are now incorporating eco-friendly practices, such as reducing energy use and cutting waste. Not only does this meet the growing demand for green practices, but it also leads to long-term cost savings.

Frequently asked questions (FAQs)

How does CRP differ from production planning in service industries?

In service industries, CRP (Capacity Requirements Planning) focuses on managing your team and time to match fluctuating demand. Unlike production planning, which deals with physical goods, CRP is all about services–things you can‘t store.

It helps make sure you can meet customer needs without overloading the system or wasting resources.

What is capacity requirement planning in operations management?

CRP in operations management makes sure that resources match production schedules. It focuses on three main areas: defining service levels, assessing current capacity, and planning for future demand.

What is capacity requirements planning in IMT (information management technology)?

In information management technology (IMT), CRP helps allocate resources like hardware, software, and staff through specialized software tools.

Key aspects of CRP in IMT include:

- Real-time data tracking – Keeping tabs on resource usage as it happens

- Demand forecasting – Predicting future needs to plan ahead

- Automated resource scheduling – Making sure resources are allocated well without manual intervention

These tools help keep IT environments running smoothly by preventing disruptions and optimizing resource use.

What is MRP and CRP?

MRP (Material Requirements Planning) is about making sure the right materials are available when you need them. It keeps production moving by making sure materials don‘t run out at important moments.

CRP (Capacity Requirements Planning) takes it a step further. It makes sure you have enough people and equipment to handle the workload.

While MRP keeps materials in check, CRP keeps your capacity in check. Both work together to keep everything running smoothly.

What is CRP in purchasing?

In purchasing, CRP helps match what you buy with the production schedule. It‘s about getting the right amount of materials at the right time–without overstocking or running short.

This keeps the procurement process on track and helps production stay on schedule.

Conclusion: Putting CRP to work in your business

At the end of the day, capacity requirement planning (CRP) helps keep your business running smoothly. By matching your resources with demand, you can avoid delays, improve productivity, and stay ahead of challenges.

To make CRP work for you: 👇

- Accurately forecast the future needs to stay prepared.

- Assess your resources regularly to stay on track.

- Collaborate with your team to adjust plans when necessary.

💡 Pro Tip: Make CRP easier with Birdview PSA. This tool lets you track resources, adjust plans in real time, and organize operations. It‘s a great way to stay focused and support consistent growth.